Serrated Blades Australia

Serrated Blades Manufacturer

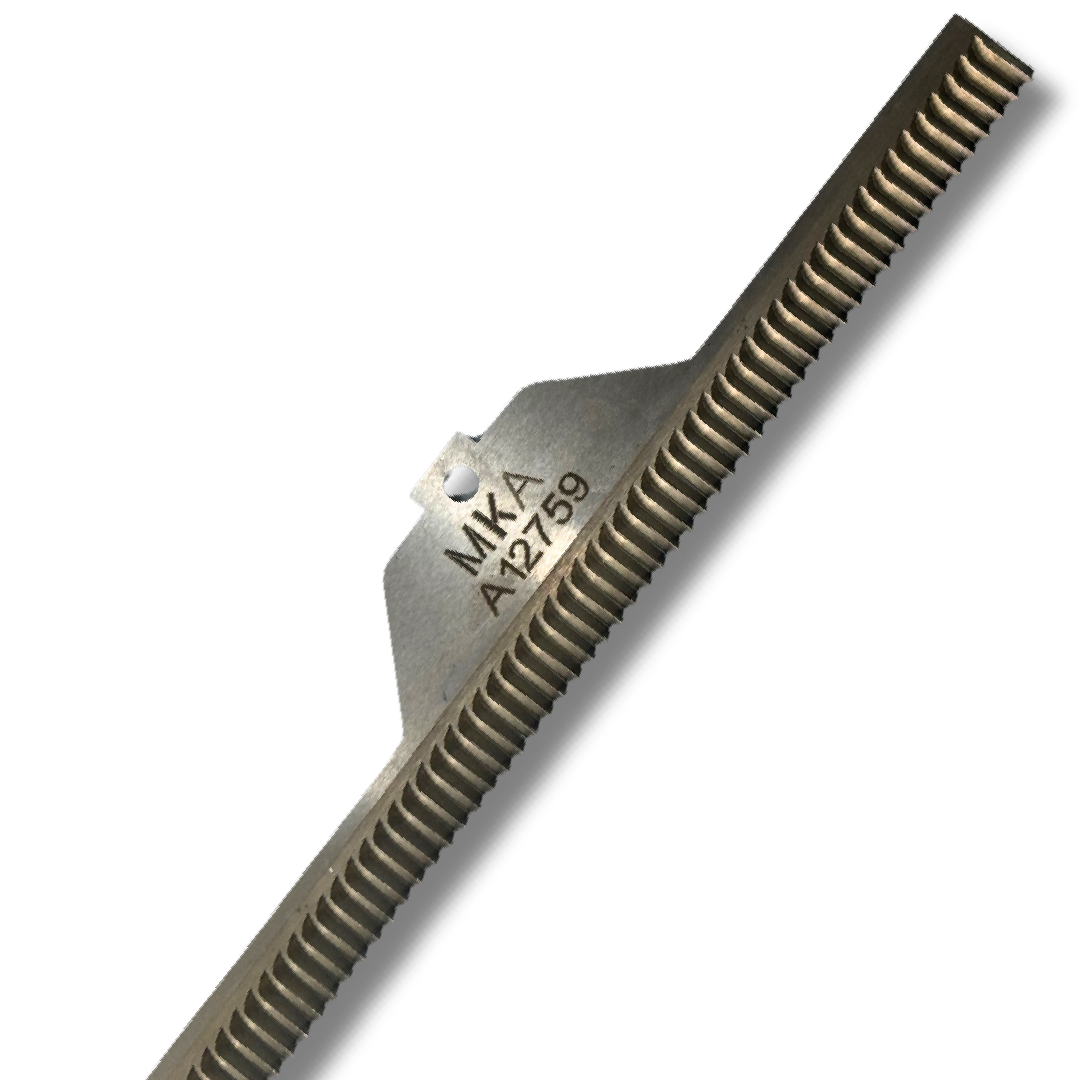

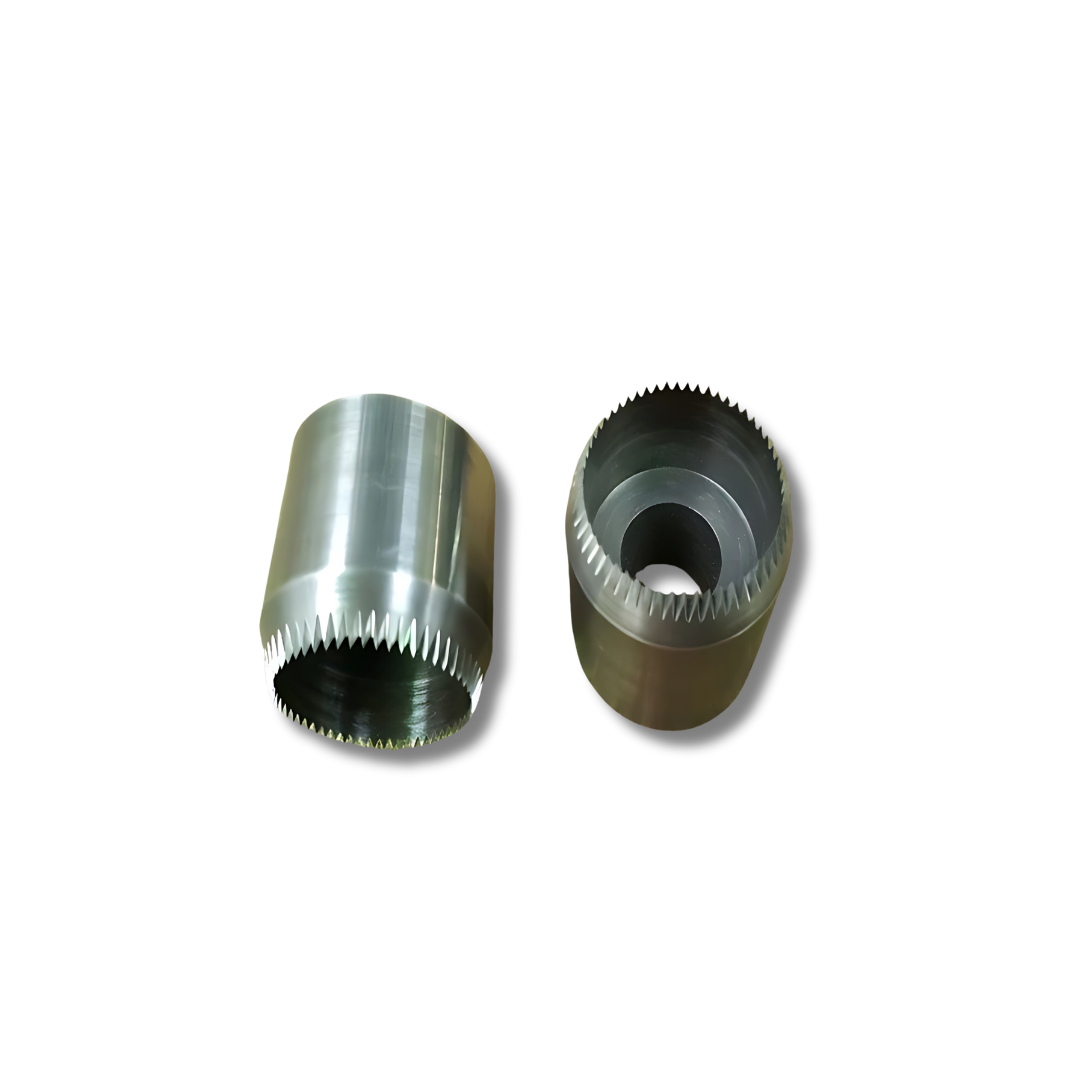

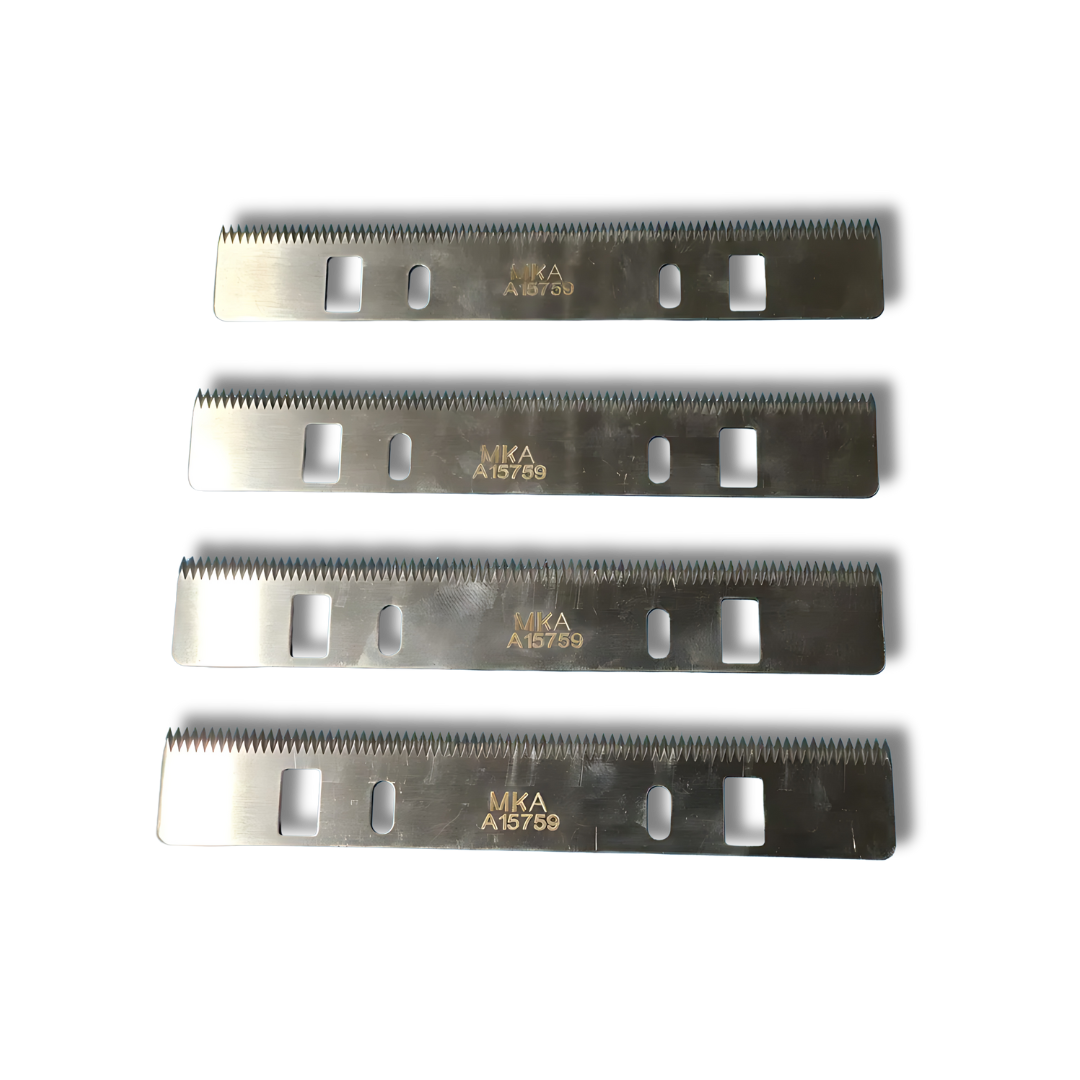

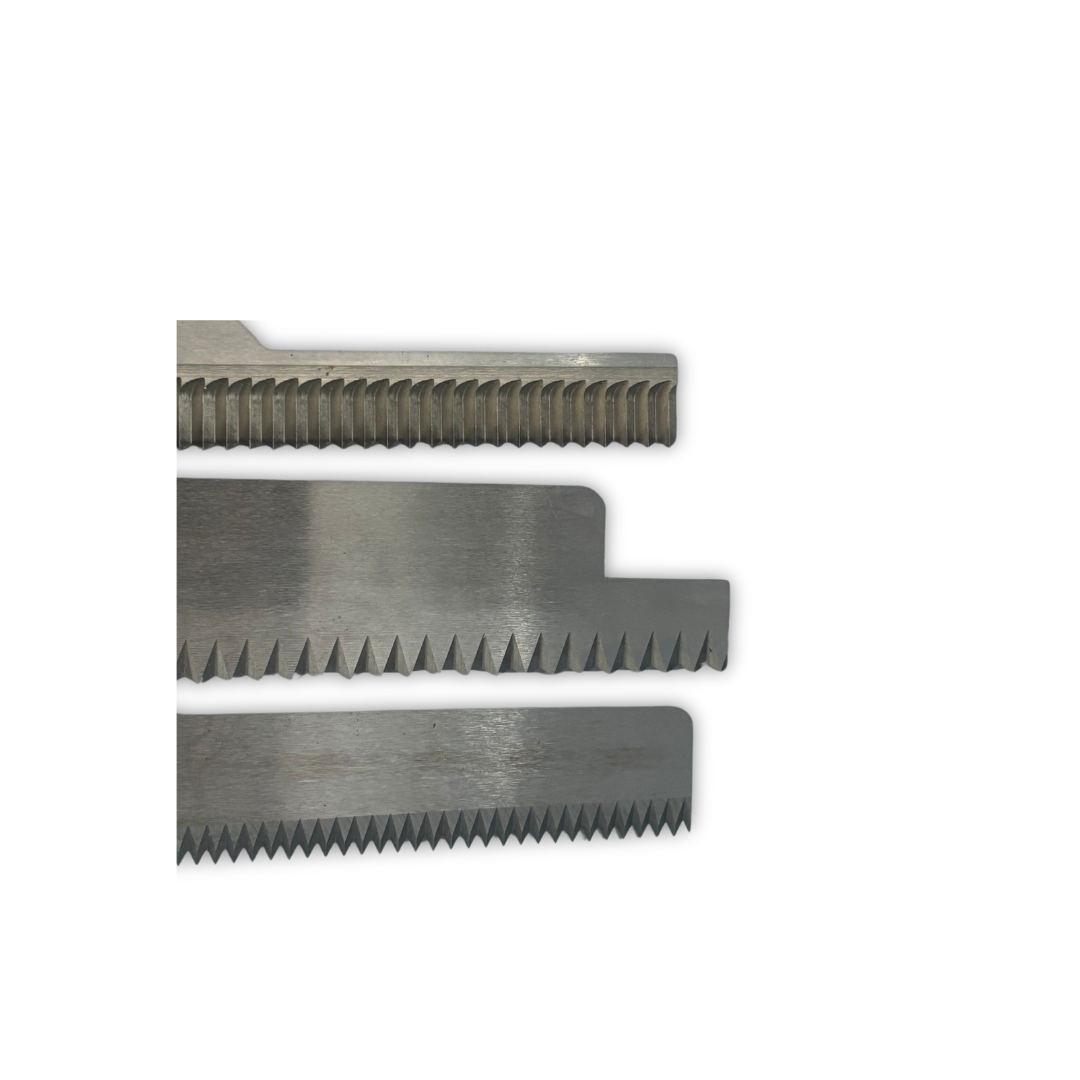

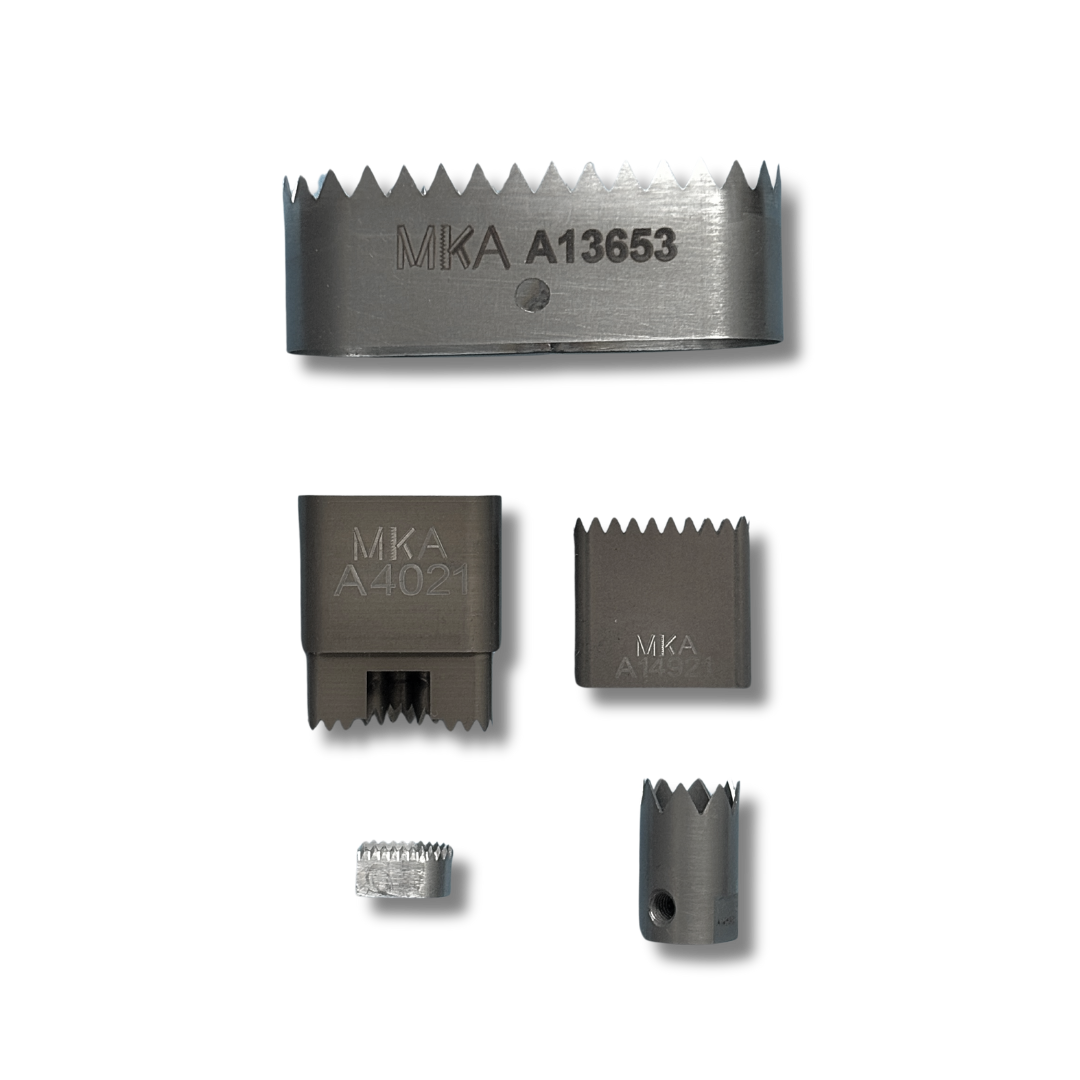

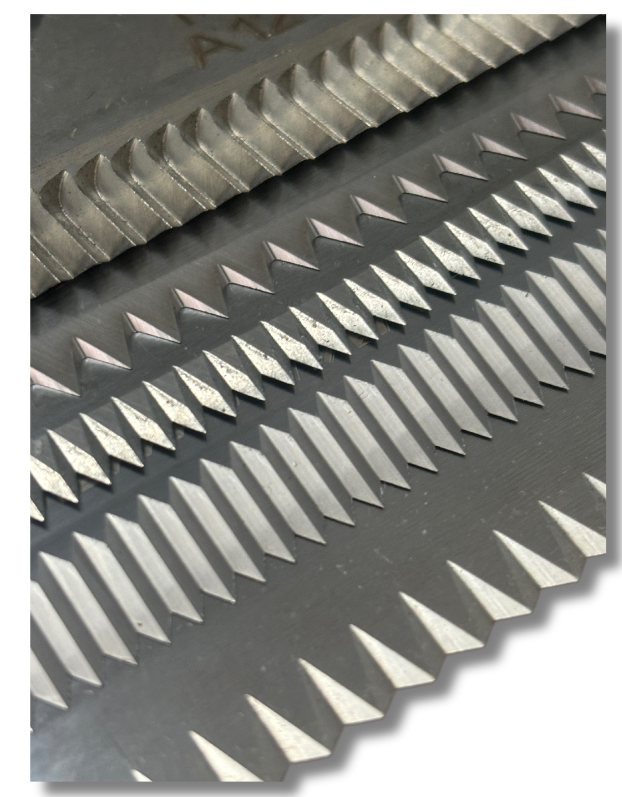

At Machine Knives Australia (MKA), our journey in producing high performance serrated blades for packaging and food machinery began in 1986. With over 37 years of dedicated experience, we have honed our craft to perfection. Our serrated blades are renowned for their precision and versatility. They are designed not only to deliver straight cuts but can also be customised for zig-zag patterns, perforations, and “easy open” cuts. Our range includes high-low teeth, serrated scallops, scalloped edges, and curved-shaped profiled blades, offering a solution for every unique application.

Efficient Sharpening of Serrated Blades

Maintaining the sharpness of serrated blades is essential for their optimal performance. At MKA, we employ advanced CNC grinding machines and internally developed equipment to re-sharpen serrated blades efficiently. Through precision regrinding of each tooth, we can restore these blades to near-new condition, ensuring your operations remain seamless.

Industries We Service

Our serrated blades find applications across a wide spectrum of industries. These industries include:

- Packaging

- Plastic Bag Making

- Paper

- Food & Product Cutting

- Insulation

- Plasterboard

Call Us Today for Your Serrated Blade Needs

At MKA, we take pride in being the preferred choice for serrated blades across these diverse industries. Our commitment to excellence and precision craftsmanship sets us apart. Contact us today to discover how our serrated blades can enhance your operations, delivering the accuracy and reliability your business demands. If you are looking for industry specific blades such as packaging machine knives, meat industry blades & saws or poultry & seafood knives. Looking for machine spare parts? MKA are a trusted manufacturer & supplier of many spare parts for many industries, such as clipper spares, extrusion dies, plastic parts & tray sealer spares we are able to meet your requirements.

Enhance your cutting tasks. Call us at 03 9545 0488.