Title or Question

Describe the item or answer the question so that site visitors who are interested get more information. You can emphasize this text with bullets, italics or bold, and add links.Title or Question

Describe the item or answer the question so that site visitors who are interested get more information. You can emphasize this text with bullets, italics or bold, and add links.Title or Question

Describe the item or answer the question so that site visitors who are interested get more information. You can emphasize this text with bullets, italics or bold, and add links.

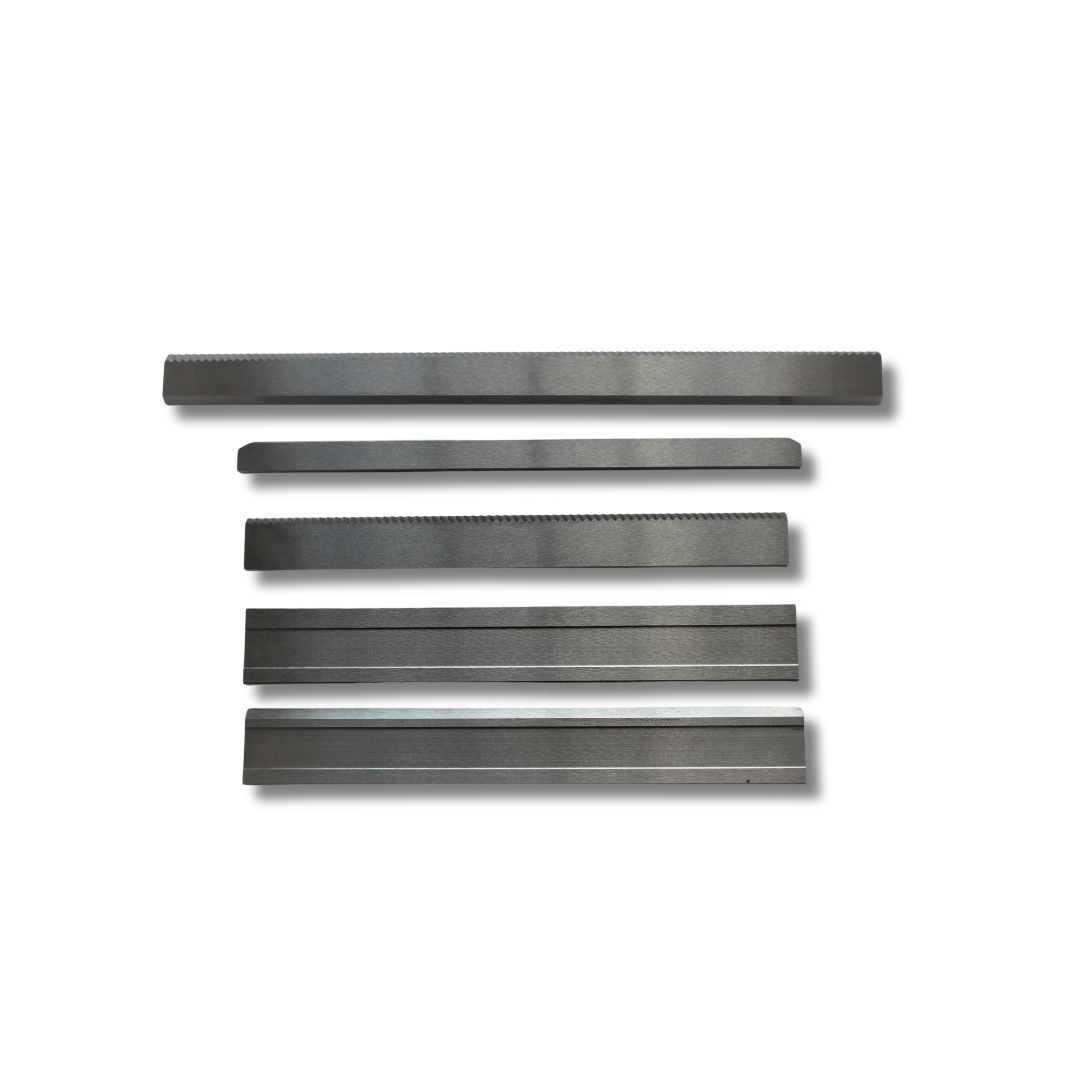

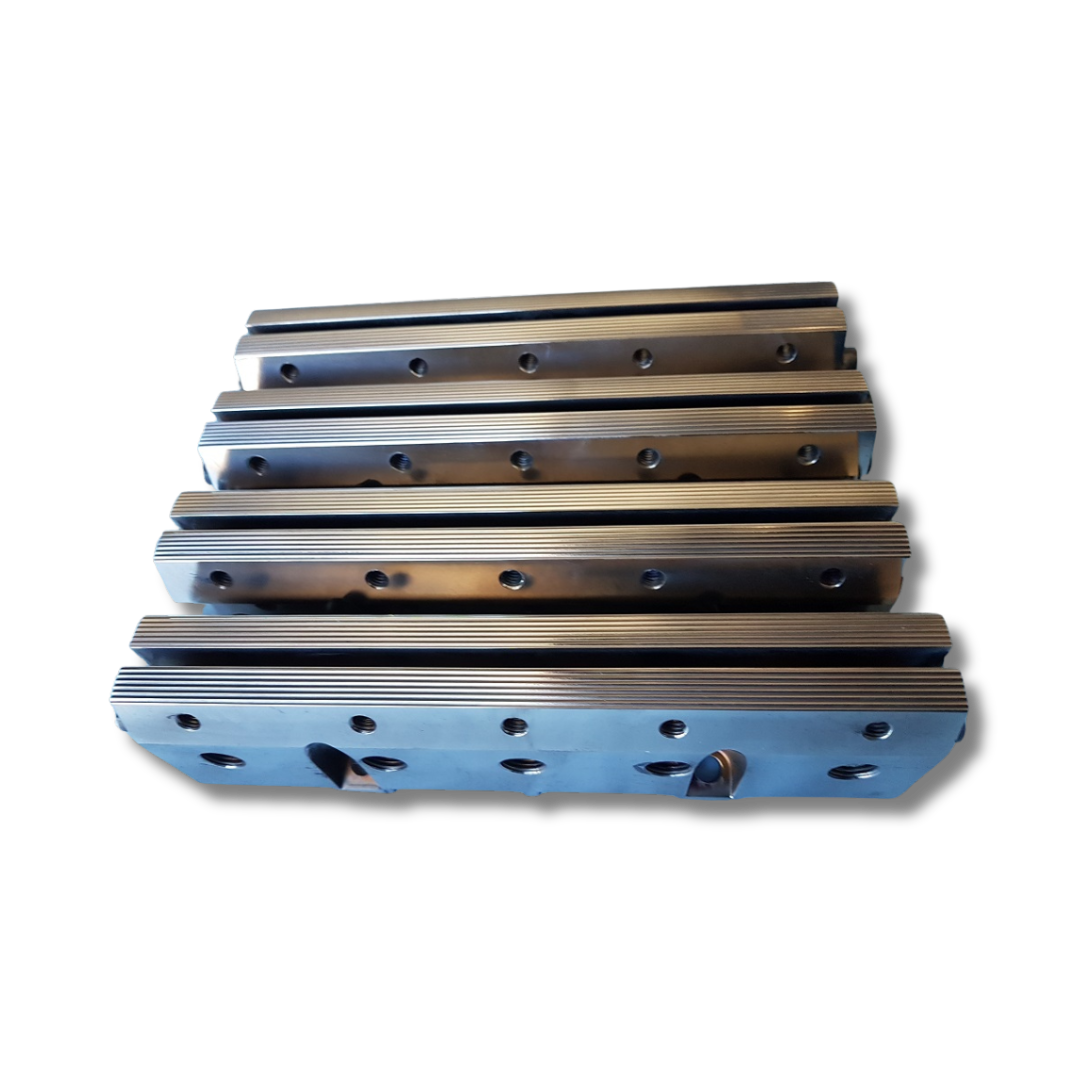

Sealing Jaws Manufacturing Australia

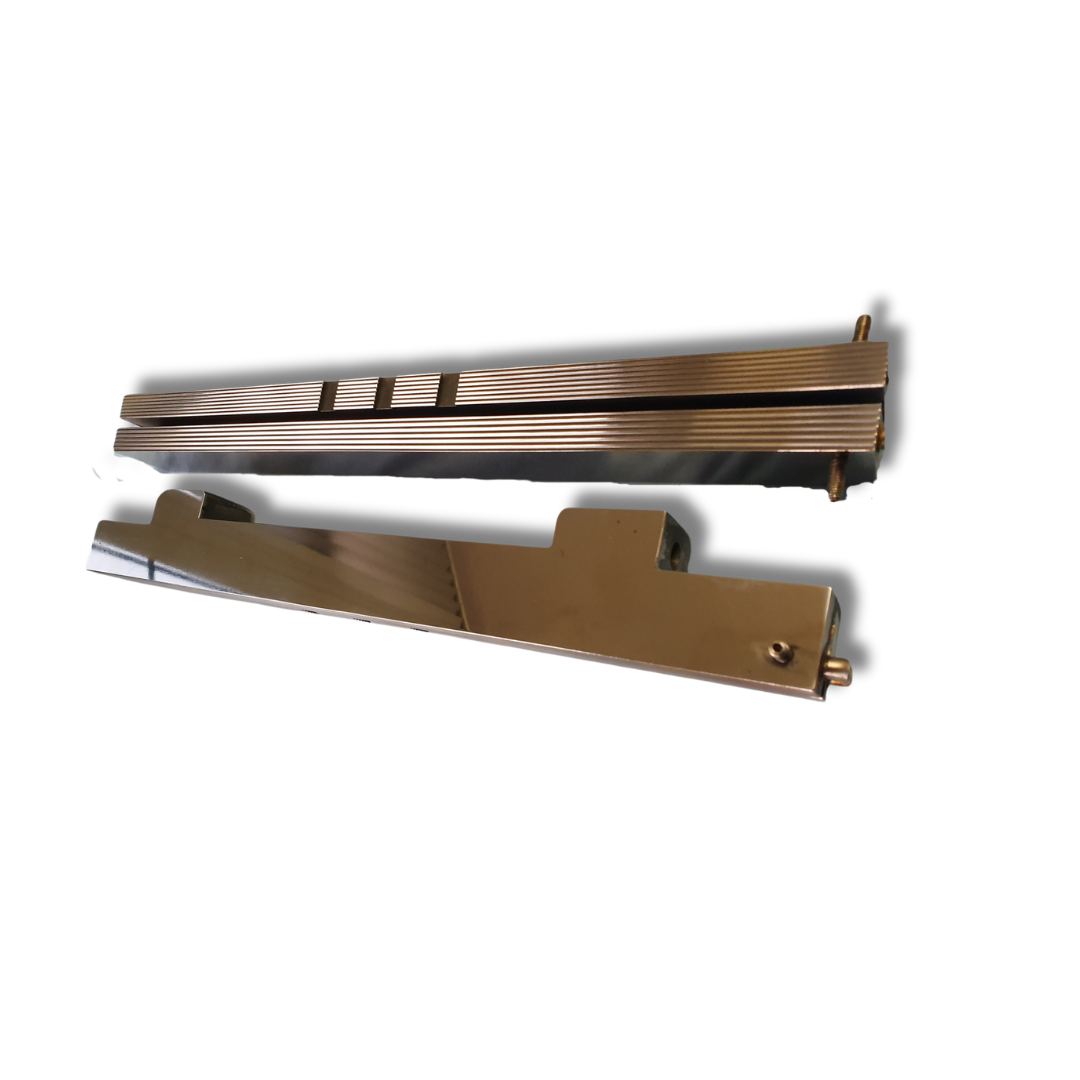

Quality Sealing Jaws and Sealing Plates for Many Industries

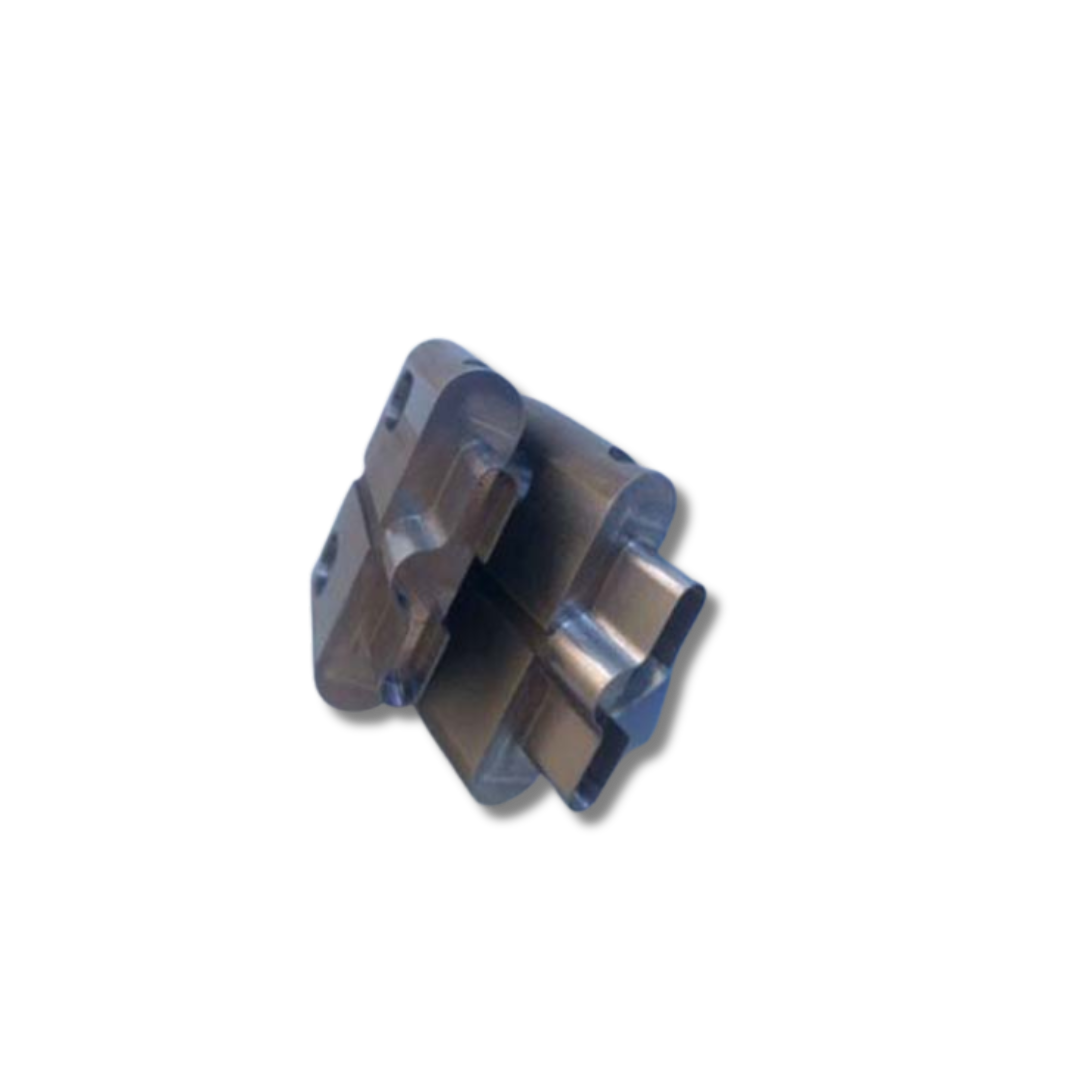

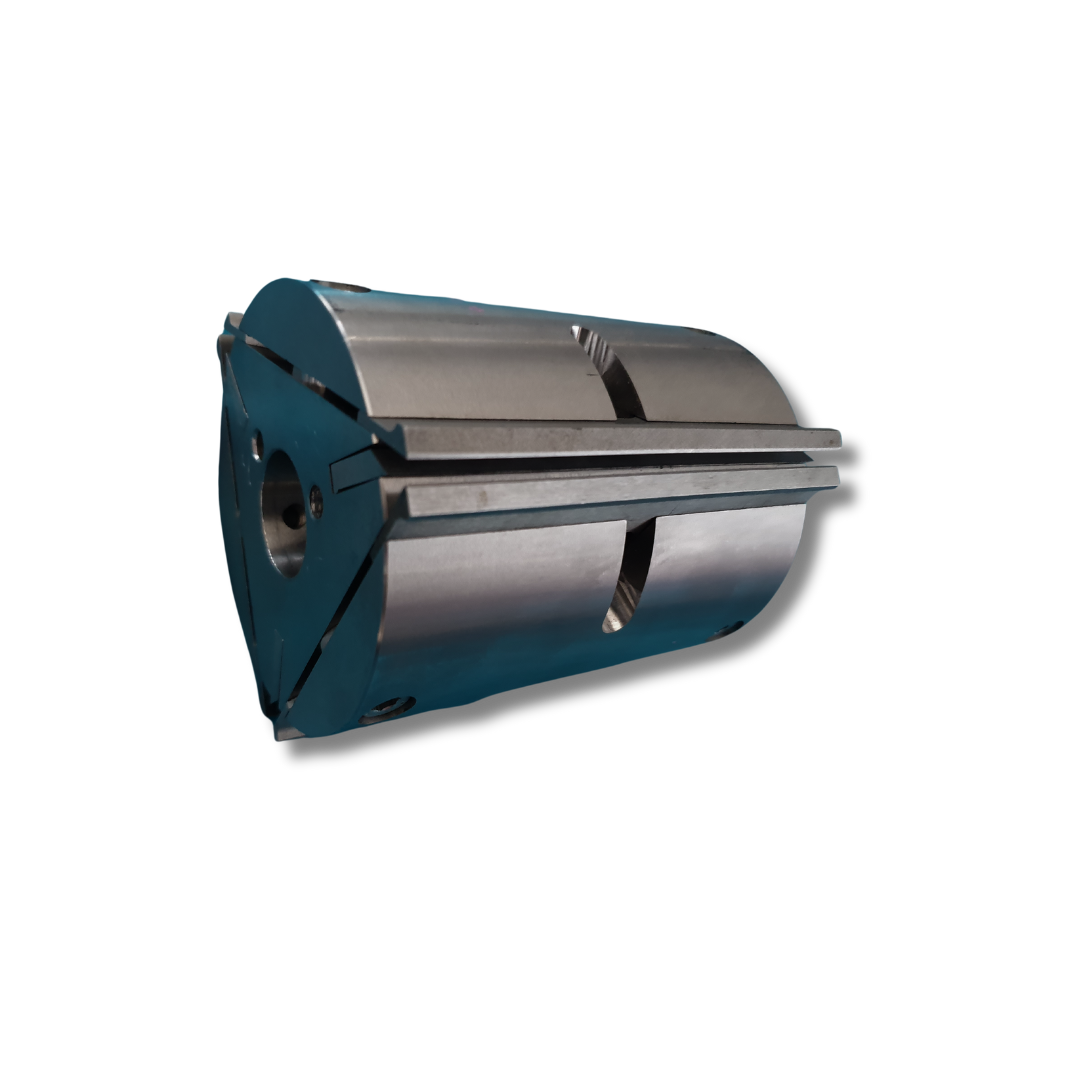

At Machine Knives Australia (MKA), we take pride in our expertise in manufacturing all types of sealing jaws, crimp blocks, rotary end seals, and sealing plates for a wide range of applications across Australia. We specialise in producing a diverse range of sealing jaws and plates tailored to meet your specific needs. Our extensive range includes sealing components for various machines, such as:

- Vertical Form Fill & Seal Machines

- Horizontal Flow Wrappers

- Sachet Machines

- Pouch Filling Machinery

- Thermo Forming Equipment

- Tray Sealing Machines

- other Specialised Packaging & Sealing Applications

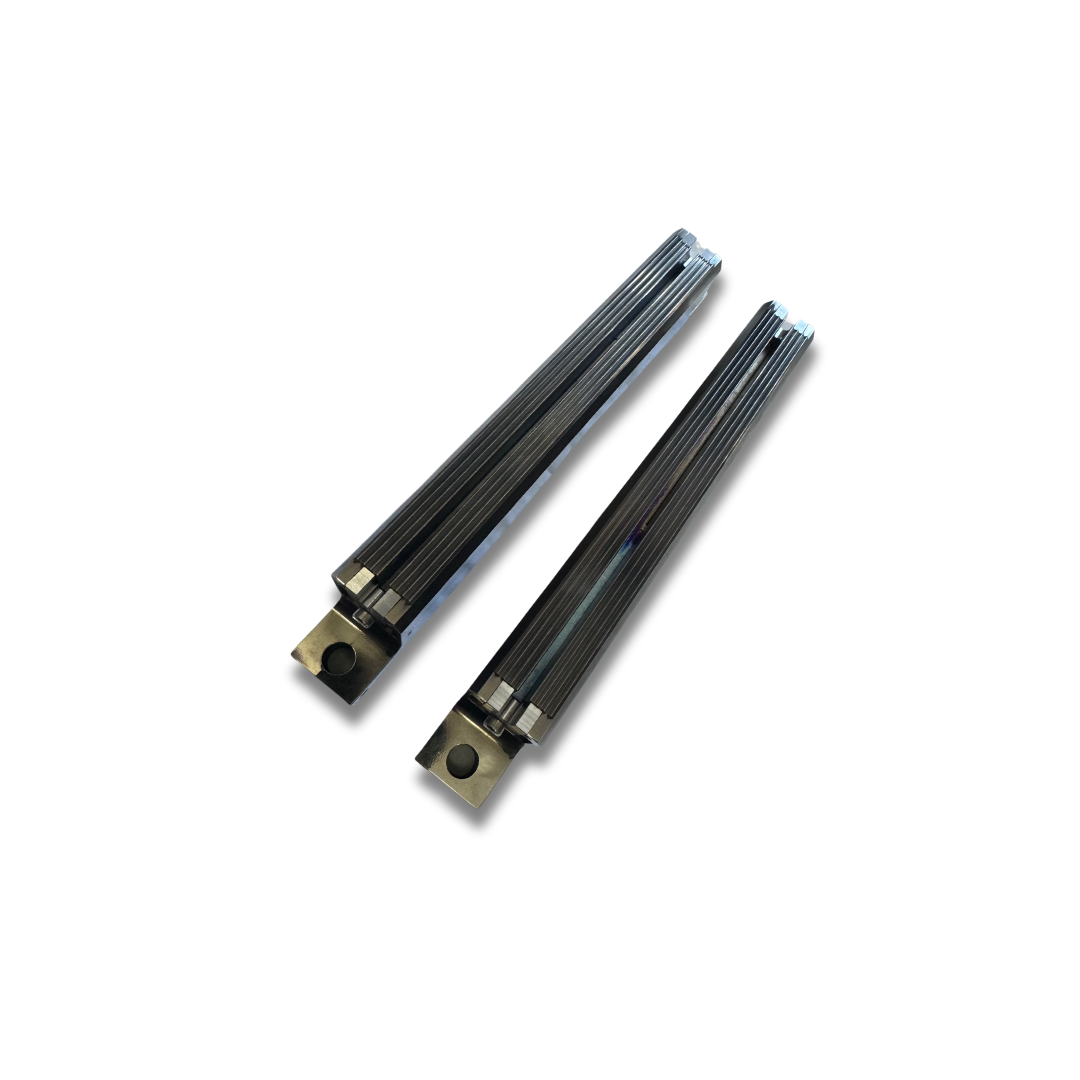

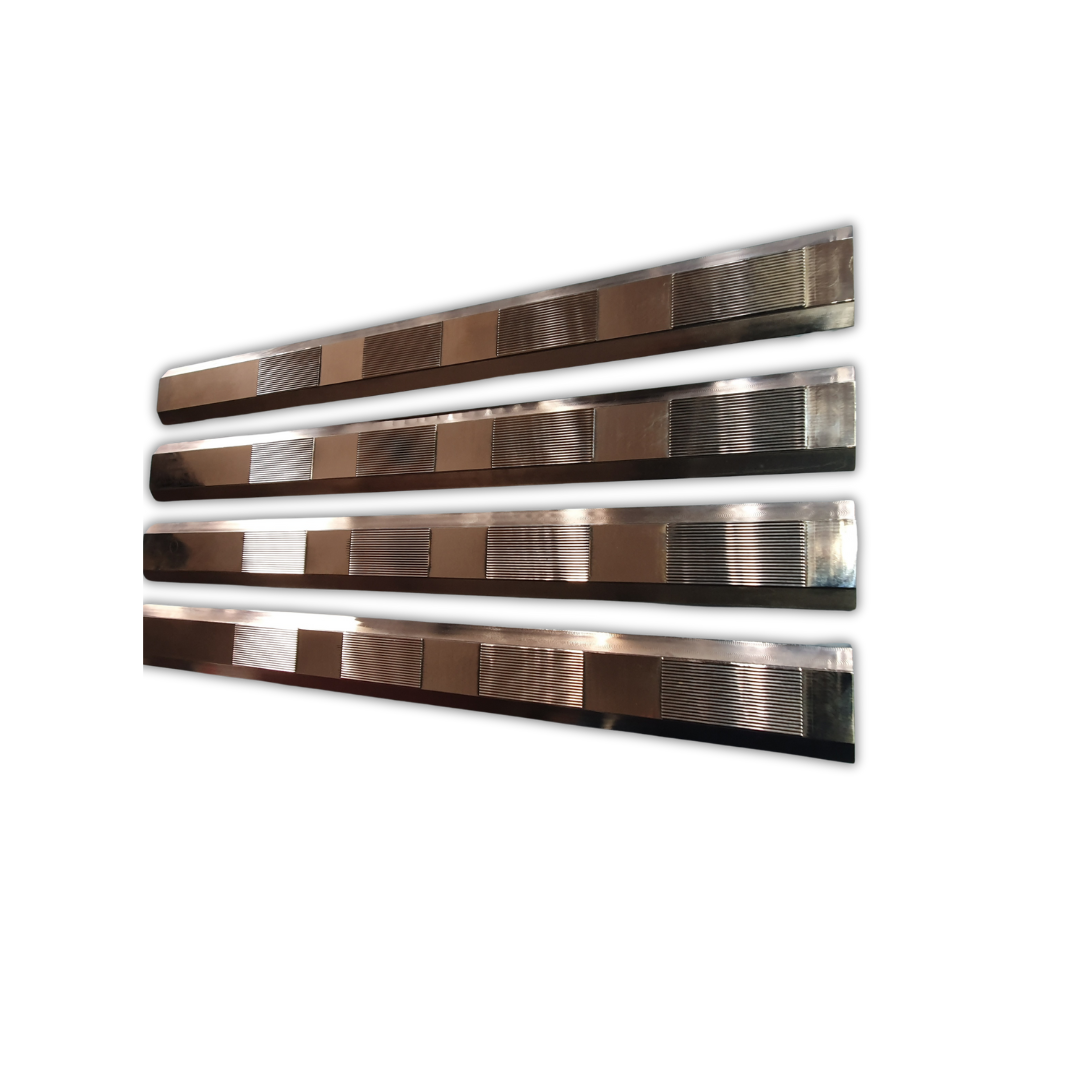

Custom Sealing Jaw & Plate Manufacturing

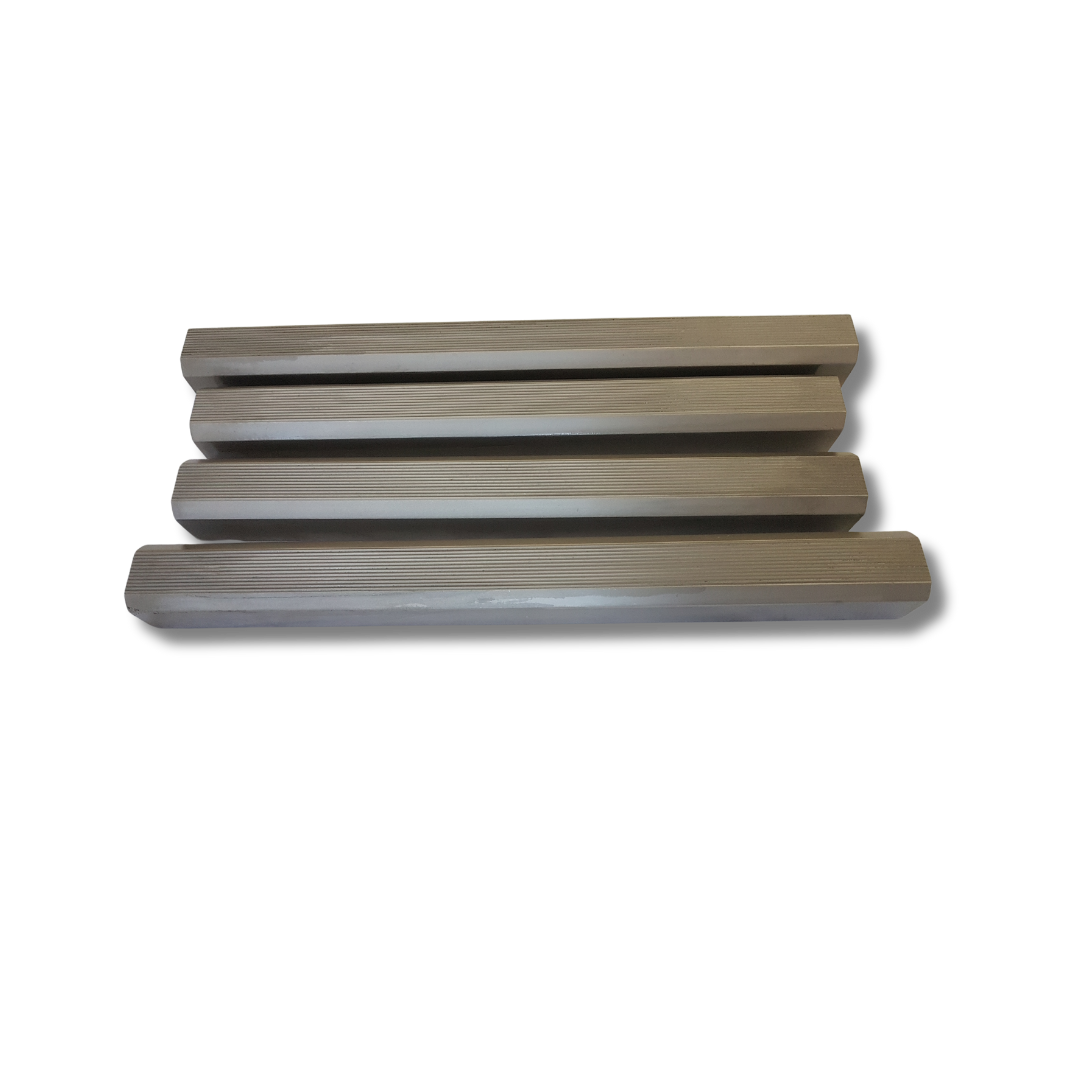

One of our key strengths lies in custom fabrication. We can craft sealing jaws and plates with any sealing pattern and profile you require. Whether it’s horizontal, vertical, criss-cross, diagonal, plain-faced, or designed to meet your unique specifications, MKA has you covered. We even offer sealing jaws with silicon-molded inserts for specific applications.

Our offerings extend to crimp blocks designed with different seals on the top and bottom of bags, making top openings effortless while ensuring a secure seal at the bottom. We also provide solutions for various hang cell and hole punch applications, as well as “easy open” requirements. Our sealing jaws cater to cold seal, constant heat, and impulse seal applications compatible with all major packaging machinery brands.

Sealing Jaws & Plate Reconditioning

MKA goes beyond manufacturing and offers reconditioning services for your existing sealing components. We can expertly re-cut sealing patterns and replating for sealing jaws, ensuring they perform optimally. If necessary, we can even modify the sealing pattern on your existing jaws to suit evolving needs.

For sealing plates used in tray sealing and thermoforming machinery, we can create custom profiles to match your specifications. Additionally, we provide recoating and reconditioning services for existing plates, helping you extend the life of your equipment.

The Benefits of Choosing Our Sealing Jaws

- Superior Sealing Performance: Our sealing jaws provide strong, durable seals that ensure product integrity and protection during storage and transportation.

- Enhanced Production Efficiency: With our sealing jaws, your production line will experience reduced downtime and increased throughput, helping you meet your deadlines with ease.

- Cost-Effective: By investing in our high-quality sealing jaws, you reduce the likelihood of seal failures, saving on material waste and additional operational costs.

Sealing Jaw FAQs

See some common questions and answers below .

Partner with MKA for Reliable Sealing Jaw Solutions

Ready to elevate your sealing process with high-quality, durable sealing jaws? Whether you're looking for a one-time order or need a long-term supplier, we’re here to meet your needs.

Contact Us Today to discuss your sealing jaw requirements and get a personalised quote. Our experts are ready to help you choose the perfect sealing jaw for your business!