New Title

Granulator Blades & Recycling Blades Australia

Granulator & Recycling Blades

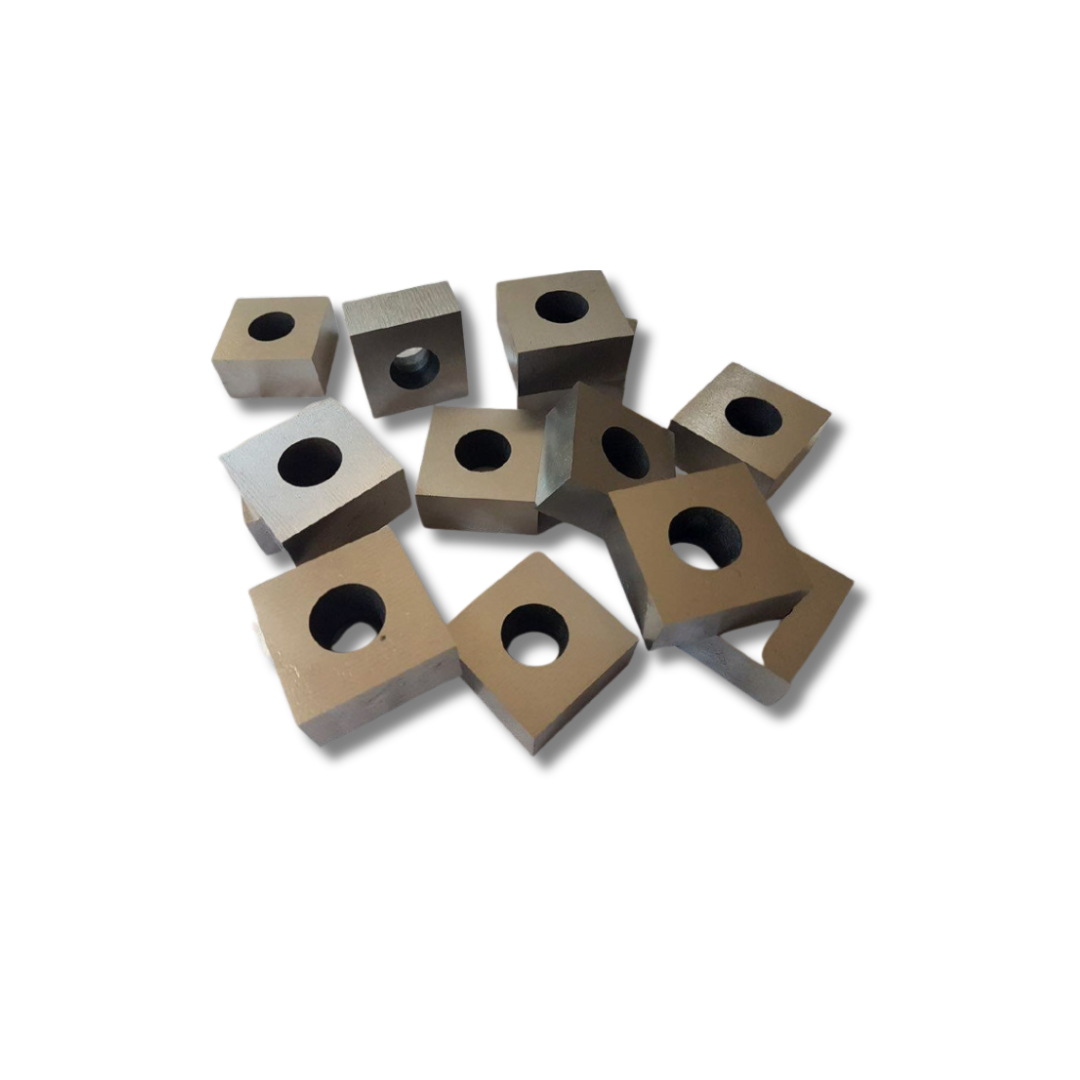

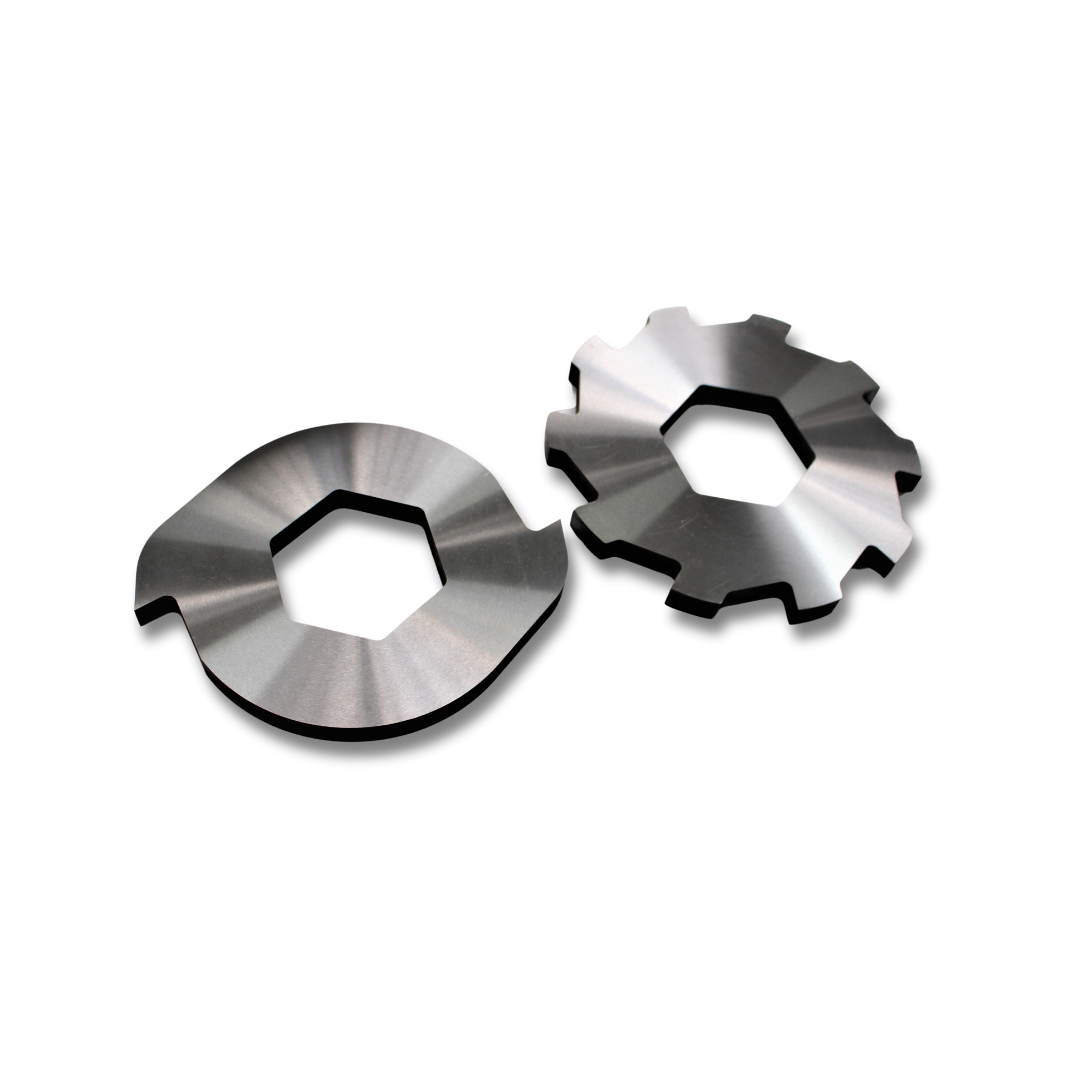

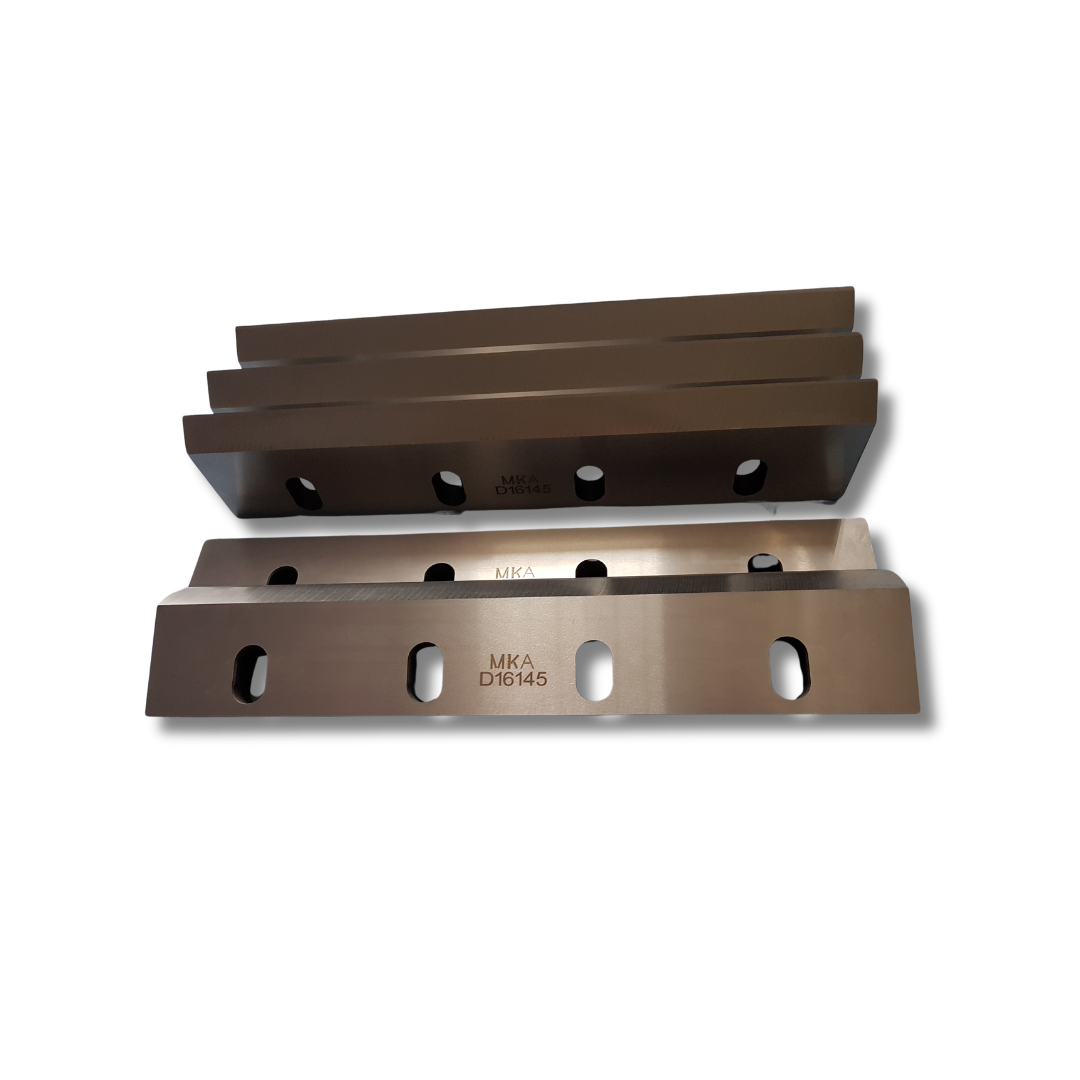

MKA supply, recondition and re-sharpens many types of granulator and recycling industry blades for businesses Australia-wide. Manufactured from materials such as tool steels, high-speed steels, knife-grade stainless steels and tungsten carbides. This is an area MKA is constantly evolving in and looking at further investment to take the next step.

Why Choose Our Granulator and Recycling Blades?

Durability: Made from high-quality materials, our blades are designed to withstand the toughest conditions, ensuring long-lasting performance.

Precision: Our blades are manufactured to exact specifications, providing a perfect fit for your granulator and recycling machines.

Efficiency: With our precision-engineered blades, you’ll experience enhanced throughput, reduced downtime, and better overall productivity.

Cost-Effectiveness: Save on maintenance and downtime with our long-lasting, high-performance blades.

Applications of Our Granulator and Recycling Blades

Our granulator and recycling blades are versatile and designed to serve a variety of industries, including:

Plastic Recycling

Granulating and recycling plastics effectively requires reliable and sharp blades. Our blades help you reduce plastic waste by efficiently processing materials and ensuring that your recycling system runs at peak performance.

Waste Management

In waste recycling and management, our granulator blades provide powerful cutting action, allowing for the quick processing of various waste materials. We help ensure that you minimise costs and increase recycling capacity.

Rubber Processing

Our blades are also perfect for rubber granulation and recycling. They ensure smooth operation in tire recycling and other rubber processing industries, reducing wear and enhancing efficiency.

Our Granulator Blade Manufacturing Process

We use advanced technology and high-quality materials to manufacture our granulator and recycling blades. Each blade undergoes strict quality control to meet the high standards expected in industrial applications.

Precision Engineering

Our blades are manufactured with precise measurements to guarantee proper fit and smooth operation with your granulator or recycling system. Each blade is rigorously tested for quality and performance.

Material Selection for Longevity

We carefully select the best materials for our blades, ensuring that they remain sharp and durable even after prolonged use. This attention to detail means fewer replacements and longer operational lifetimes for your machinery.

Granulator Blades FAQs

See some common questions and answers below

Buy Precision Granulator Blades Australia

At MKA, we don’t just offer top-quality granulator and recycling blades — we provide complete cutting solutions for your business. Whether you need meat processing blades, poultry & seafood blades, packaging knives, or product cutting knives, our precision-engineered blades deliver unmatched performance, durability, and efficiency to keep your operations running at peak productivity. Don’t settle for less — explore our full range of high-performance blades today and discover how we can help you boost efficiency, reduce downtime, and increase profitability. Visit our website now and take your business to the next level!