Extrusion Dies Australia

Extrusion Dies for Many Industries

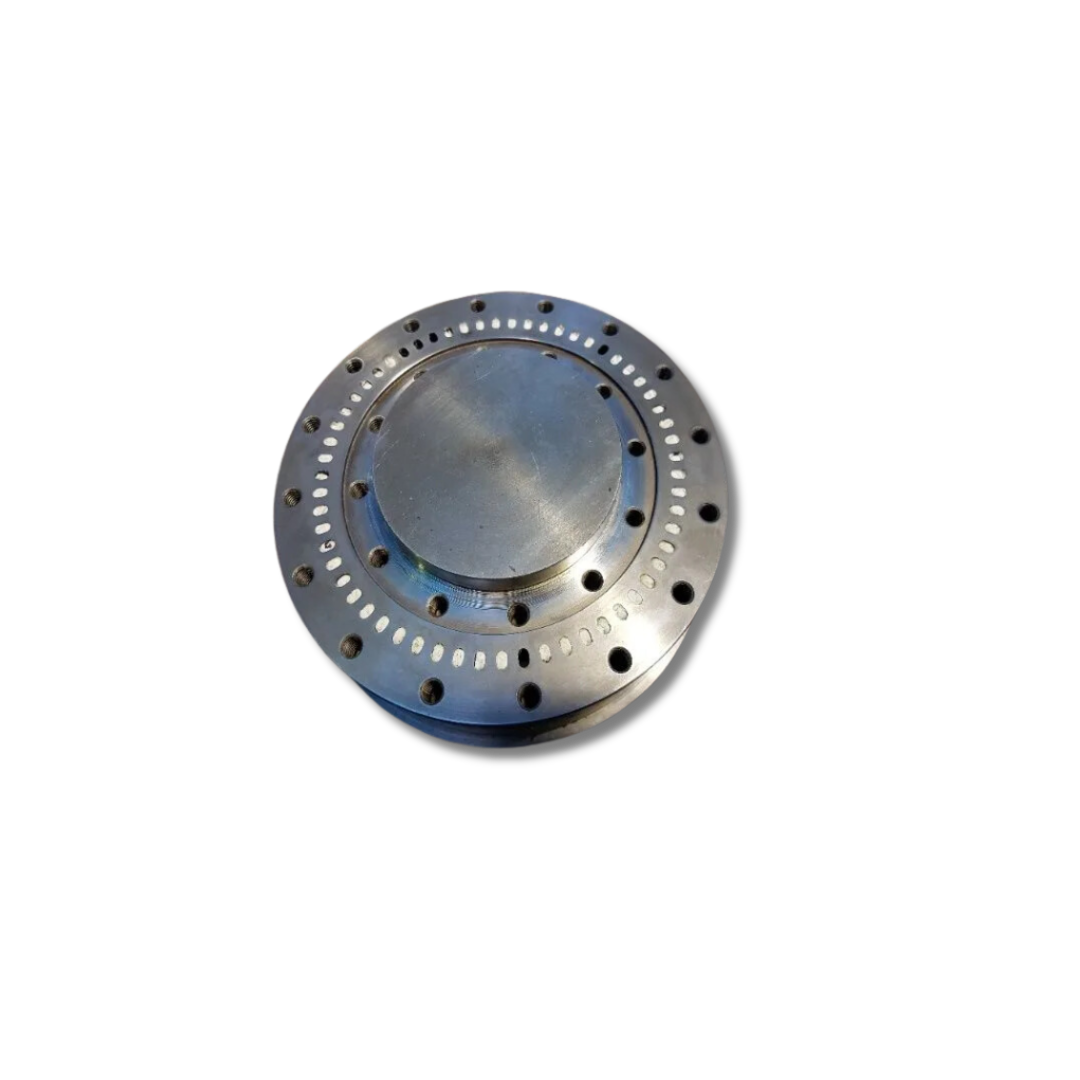

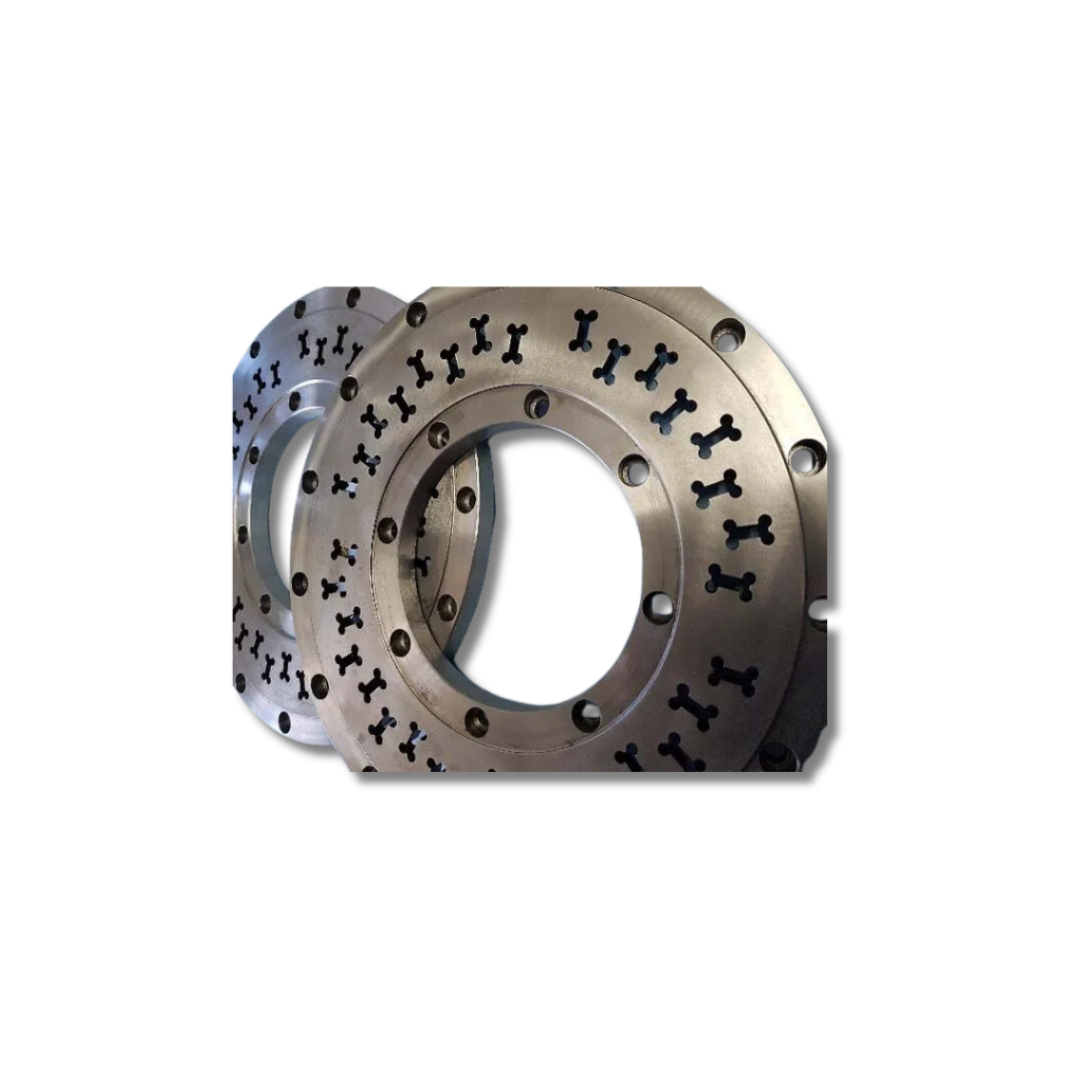

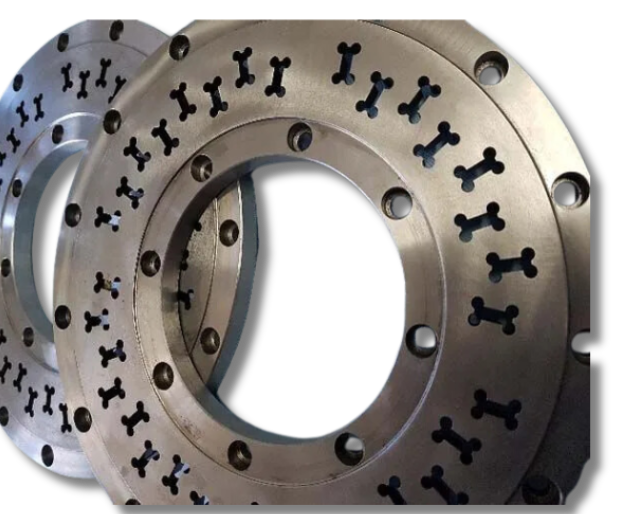

MKA has the ability to make extrusion dies for many industries across Australia, including food, bakery, pasta, pet food, rubber, biscuit and pastry, with our state-of-the-art equipment, including EDM wire cutting combined with 3, 4 and 5 axis CNC Machining, CNC Turning plus Water Jet Cutting Technology. This basically gives us the ability to make economical parts when precision is not required but also the ability to make high-accuracy parts as required.

We can make many varied shapes and profiles from many materials. We have flexibility rarely matched in this area.

Extrusion Die FAQs

Learn More About Extrusion Dies Below

What is a die for extrusion?

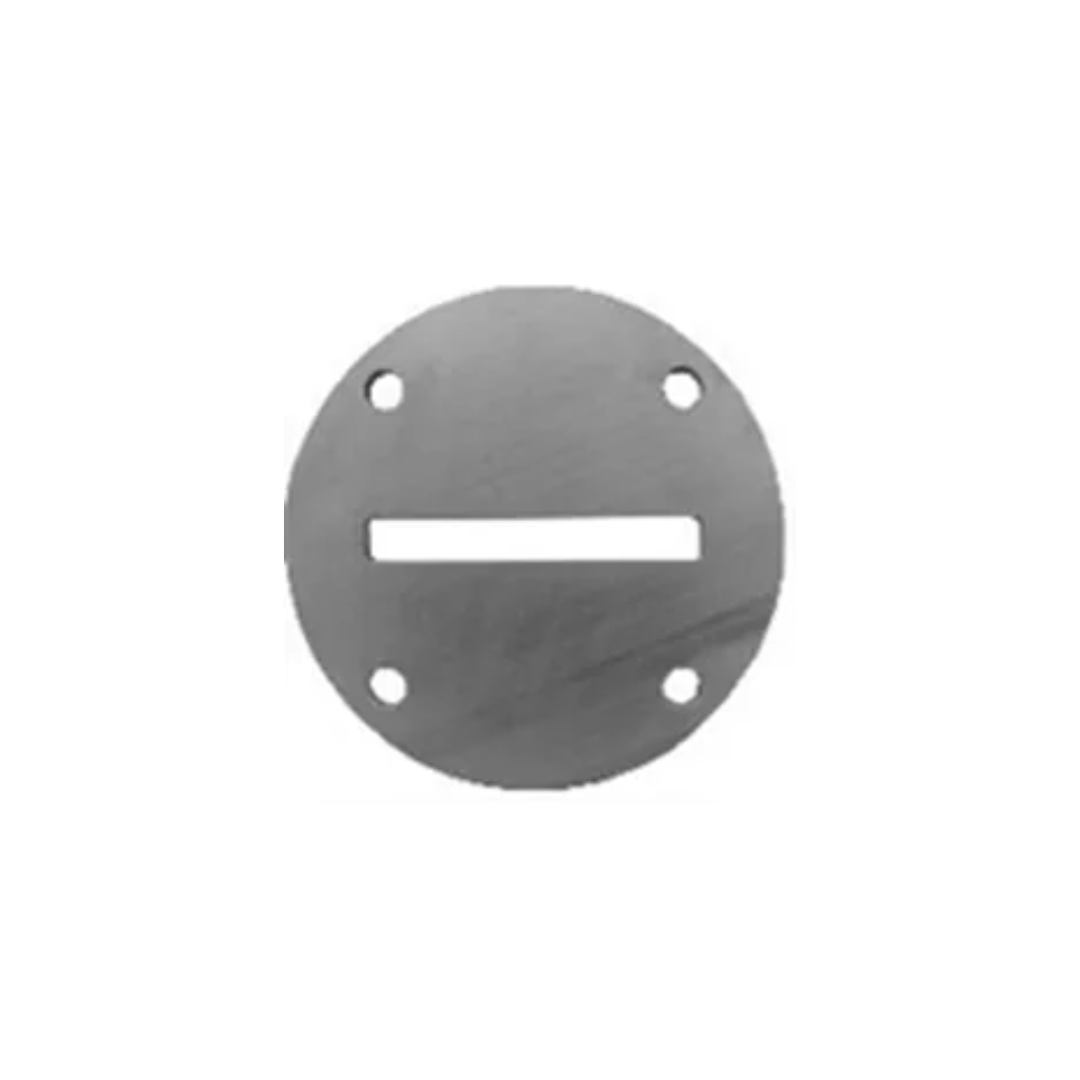

A die for extrusion is a specialised tool used to shape molten material as it is forced through during the extrusion process. Typically made from durable materials like steel or tungsten carbide, the die features a specific opening that defines the profile and dimensions of the final product.

When molten material, often plastic or metal, is pushed through the extruder, it flows through the die's opening, taking on its shape. Dies can be designed for various applications, creating items such as pipes, sheets, and custom profiles.

The design of the die is crucial, as it not only influences the final shape but also impacts factors like material flow, cooling rates, and surface finish. A well-designed die ensures consistency and quality in the finished products, making it an essential component in the extrusion process across multiple industries.

What role does the die play in the extrusion process?

The die plays a pivotal role in the extrusion process by determining the final shape and profile of the extruded material. Positioned at the end of the extruder, the die shapes the molten material as it is forced through. Its design is critical; the die's opening defines the dimensions and contours of the finished product, whether it be pipes, sheets, or custom profiles.

Additionally, the die helps control the flow of the molten material, ensuring uniformity and consistency in thickness and shape. This is essential for maintaining product quality and meeting specific industry standards. Furthermore, the die can influence material properties by affecting cooling rates and surface finish, which are crucial for the performance of the final product. Overall, the die is essential for transforming raw materials into useful shapes efficiently and accurately.

What are extrusion dies used for?

Extrusion dies are used to create a wide variety of products across multiple industries. In the plastics industry, they shape materials into items like pipes, sheets, and films, enabling efficient production of everyday products such as containers, packaging, and construction materials.

In the metal industry, extrusion dies help produce components like aluminum frames and structural parts, which are essential in construction and manufacturing. They are also used in the food industry to create products like pasta and snacks, where specific shapes and textures are important.

Overall, extrusion dies facilitate the mass production of consistent, high-quality shapes, making them vital in industries ranging from automotive to consumer goods, contributing to both efficiency and innovation in product design.

How do extrusion dies work?

Extrusion dies are crucial tools in shaping materials by forcing them through a specially designed opening. The process begins with raw material, usually in pellet form, fed into an extruder. Inside the heated barrel, the material melts as it is pushed forward by a rotating screw.

Once molten, the material is forced through the die, which has a specific shape or profile. As it exits, it takes on this desired form, creating continuous shapes like pipes, sheets, or profiles.

After passing through the die, the shaped material is cooled, typically using air or water, solidifying into the final product. This process is widely used across industries such as plastics, metals, and food production, transforming raw materials into functional products efficiently and consistently.

Explore our extrusion die options. Contact us at 03 9545 0488 for tailored advice.